This spiral timber is a special feature in our new showroom. Cutting this amazing white pine spiral took Stephen about 40 hours! White pine is readily available in our region, and is an attractive honey color. Low shrinkage, minimal cracks and twists are some of the benefits of working with this timber species. Stephen documented this involved process and the photographs below show the steps.

Spiral Timber Process

Stephen started with a 12" x 12" white pine timber

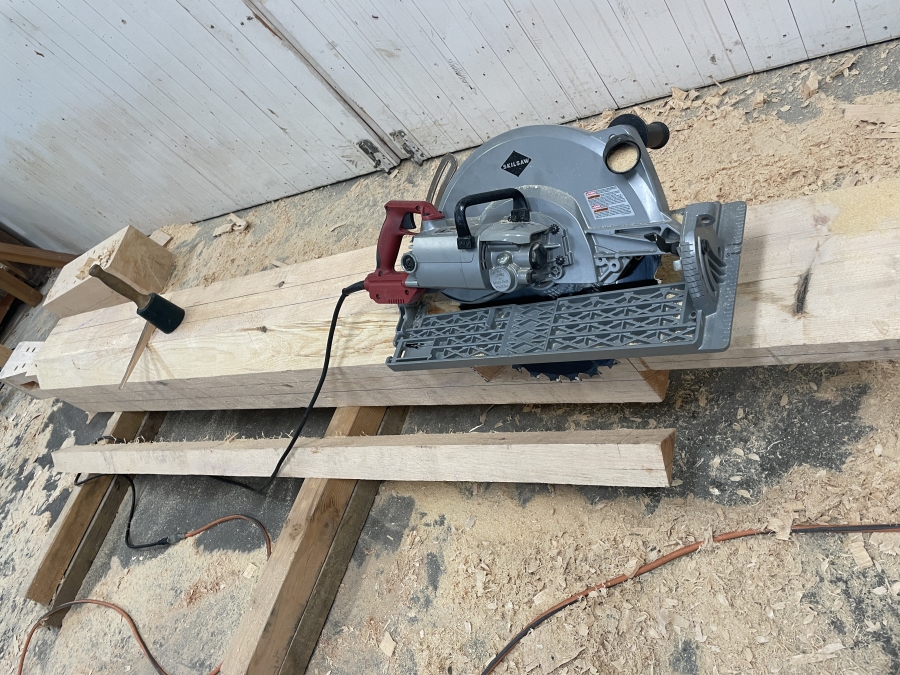

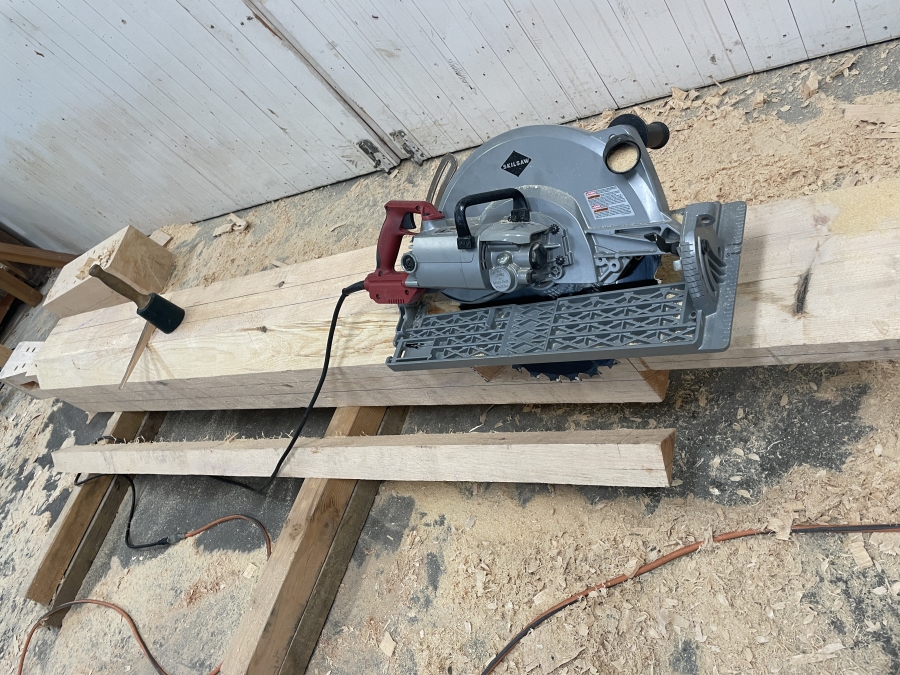

The timber was first cut to length

Mill the timber to the exact size

Resawing the timber to ensure accuracy

Verifying accuracy is always important

Next, layout the center lines

Layout the square joinery

Layout the through tenon

Layout the post top tenons

Cutting joinery by hand

Cutting the the square timber into an octagon

Cutting the octagon

Octagonal is the new shape!

Next step - power plane to take the timber from octagon to round

Begin making the timber round

Continue rounding

Now for the 8"x8" layout

Spiral is laid out first with string

Then the spiral is drawn on the timber

Next step is to start kerfing

Use a mirror to assist with kerfing

The mirror allows you to see around the curve of the timber

Blue tape is used to reference the spiral over joinery that was already cut in the timber

Cleaning kerfs, removing the cut pieces of timber

Cleaning more kerfs

Cutting more with the chainsaw

Be precise with the depth of these cuts

More kerfing

Blue tape is covering the joinery

All four sides are now roughed out

Milling one side flat on the sawmill

Spiral is mostly cleaned

Milling the flat side

Flat side will go against the wall

Spiral is finished and ready for test fit

Test fit

Fit up